Glenn Metalcraft Inc. of Princeton, Minn., is a case in point. The company was founded in 1947 as a tool and die shop, and has been growing ever since. Through the years, the third-generation, family owned company has built on its core competency of metal spinning while continually adding capabilities, capacity and automation to meet customer needs. Under the leadership of CEO Joe Glenn, Glenn Metalcraft has grown into Elemet Group, consisting of Minnesota Industrial Coatings, also in Princeton, Elemet Manufacturing in Aitkin, Minn., and a second Glenn Metalcraft location in Ft. Worth, Texas. By the end of 2023, the company plans to move into a larger Princeton facility for a total of 169,000 sq ft [15,700 sq m].

LASER FOCUS

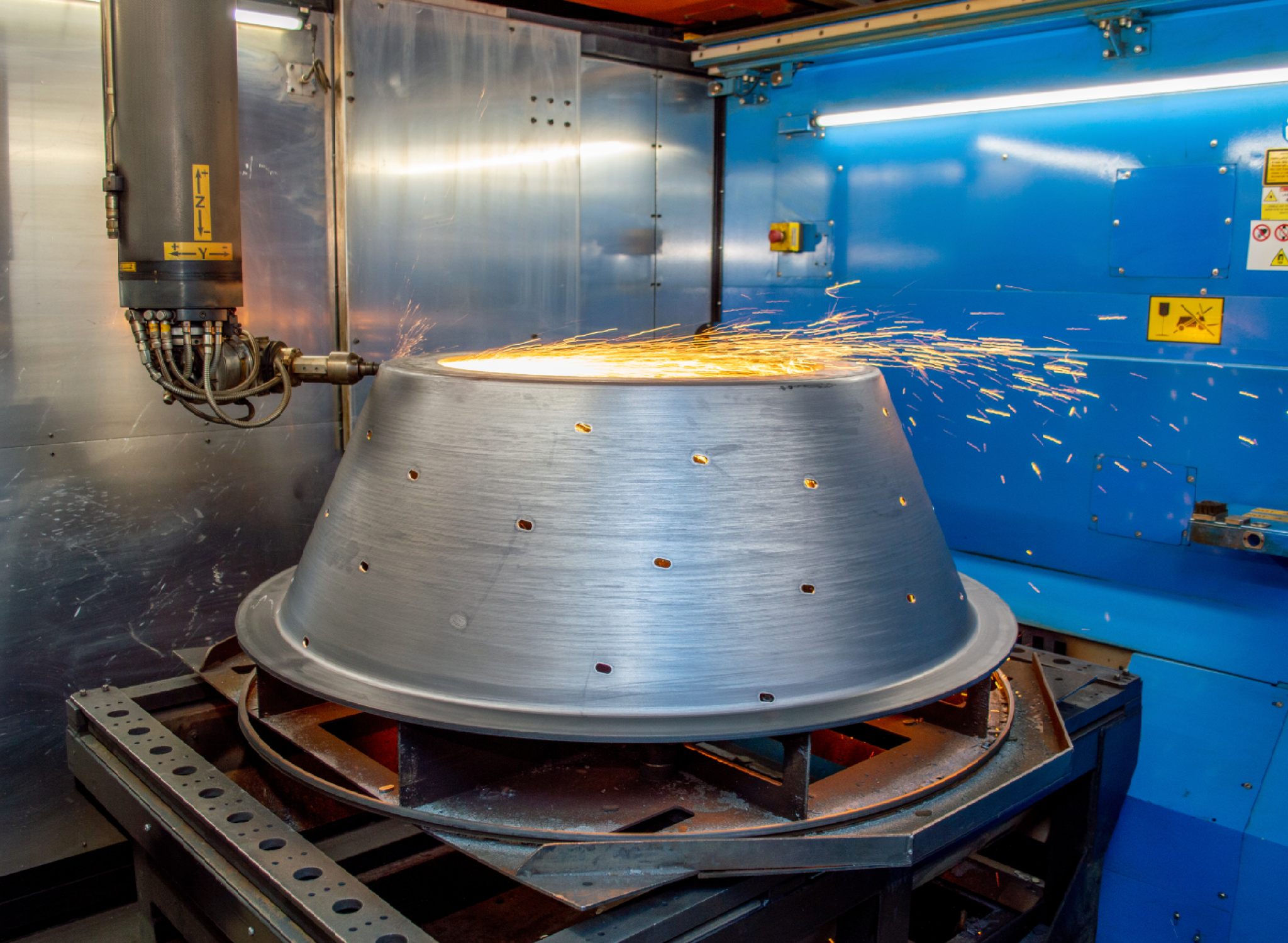

While Glenn Metalcraft has the capability to provide fabrication and welding, spinning remains its core business, explains President Dan Patnode. “We were one of the first U.S. companies to invest in CNC spin-forming technology, and we continue to lead the industry in high-quality, close-tolerance, heavy-gauge metal spinning.” The company specializes in heavy-gauge metals for agriculture and construction applications. And a critical part of its strategy is vertical integration and expanding its capabilities, which is why Glenn Metalcraft has acquired various painting, machining and waterjet operations. “We have put ourselves in a position to manufacture and provide in-house finished parts for our OEM customers,” Glenn asserts.

More recently, Glenn Metalcraft has transitioned from waterjet cutting to laser technology with the help of Prima Power North America Inc. Prior to 2020, Glenn Metalcraft had been using a waterjet to cut the thickness of its production parts. “We were cutting five-axis on the waterjet for years, because the 3D lasers were unable to cut the thickness that we needed to process our heavy-gauge parts. Our parts were too thick for the technology at that time.” But Glenn Metalcraft’s growth, coupled with evolving customer needs prompted a change. “We were a very competent, skilled, waterjet company. So we were at the max of what those machines could do from a throughput standpoint, and it just wasn’t enough,” Patnode says. At the same time, laser technology had advanced to the point where Glenn Metalcraft was not only ready to make the switch— it wanted to go big. In March 2020, the company ordered the largest model available, Prima Power’s 4-kW Laser Next 2141, for its Princeton facility.